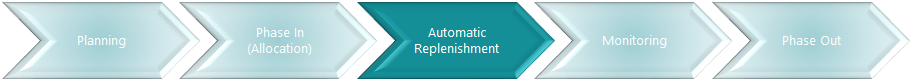

Automatic Replenishment covers all steps from calculating Out-of-Stock, current inventory and demand, journals, thresholds until finally creating the Purchase Orders, Transfer Orders or Sales Orders.

The Out-of-Stock calculation detects on item, variant, location and day level occurrences of out-of-stock situations.

This serves two purposes:

- Information about occurrence and duration of out-of-stocks

- Input for the RIQ and Journal calculation, since out-of-stock days are treated differently in the demand calculation for the calculation method Average Usage.

Goal

The goals of this step:

- Gain understanding if OOS functionality is needed

- For information purposes

- For RIQ calculation

This applies only, if one or more items are calculated by using the Replen. Calculation method Average Usage

- Set up the processes for the calculation in LS Central

Key questions / considerations

General

- Are Out of stock situations an issue and shall those be monitored?

- Is the Replen. Calculation method Average Usage in use for one or more items?

Setup

- How many SKU's (item, variant and location combinations) need to be calculated?

- If this is exceeding 1mio. SKU's

or calculation time is too long:- Activate query-based processing

- Activate parallel processing

- If this is exceeding 1mio. SKU's

Setup considerations

Replenishment Setup

Out of Stock calculation needs to be enabled in the Replen. Setup page by activating the Stock Out Functionality field.

Out of Stock calculation

Out of Stock can be calculated manually or via a Scheduler Job.

To run the calculation manually by using the report Replen. Upd Out of Stock in Departments - LS Retail - Replenishment - Periodic Activities.

It is recommended to use the Scheduler Job calculation. Details, how to set this up can be found here: Out of Stock Days

The result of the Out of Stock calculation can be seen in the page Replen. Out of Stock Days. This page can be accessed from the Departments - LS Retail - Replenishment - Automatic menu.

Performance tuning

To improve the calculation performance for installations with a high number of items, variants and locations there are two options:

- Query based processing

- Parallel processing

Both options can be used together, if needed.

Query based processing:

This can be enabled in the the Replen. Setup page by activating the Out of Stock - Enable Query field. When this is enabled, the calculation will make use of Business Central query objects and temporary tables. This will consume more physical RAM memory on the service tier as the standard calculation approach but will reduce calculation time.

Parallel processing:

The calculation can be split between multiple service tiers where each service tier will only calculate a part of the entire item scope. The service tiers can be run on the same VM or server.

More details, how to setup the parallel calculation approach can be found here: Replenishment Calculation using Multiple NAS LS Nav 2017 (10.06) Memo.pdf

Go back to: